18 Types Of Roof Shingles

Table of ContentsDifferent Types Of Roofs That Increase Home Value3 Of The Best Roofing Materials For Arizona HousesWhat Is The Longest Lasting Roofing Material?Most Popular Roofing Materials

Cool It: The 5 Best Roofing Materials For Hot Climates

Cool It: The 5 Best Roofing Materials For Hot Climates

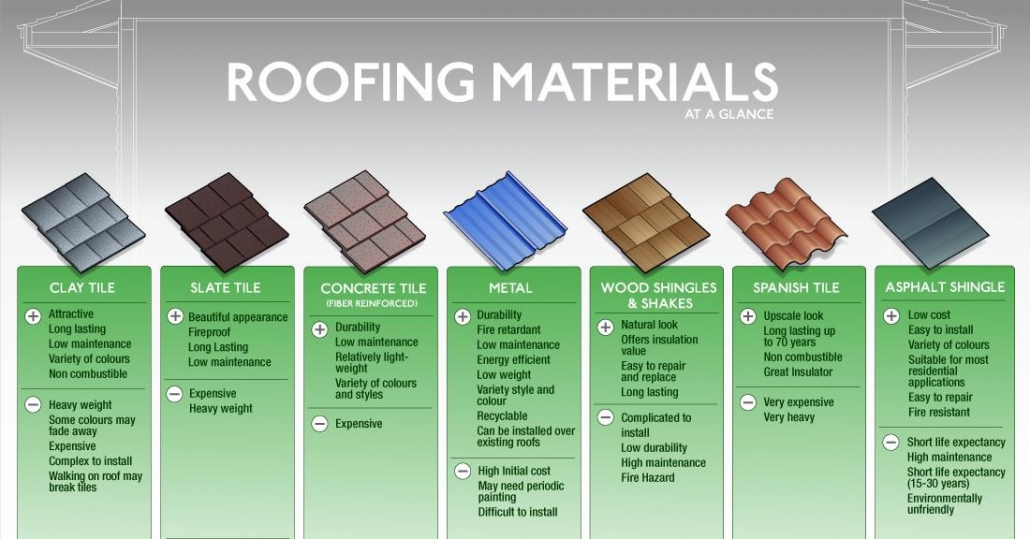

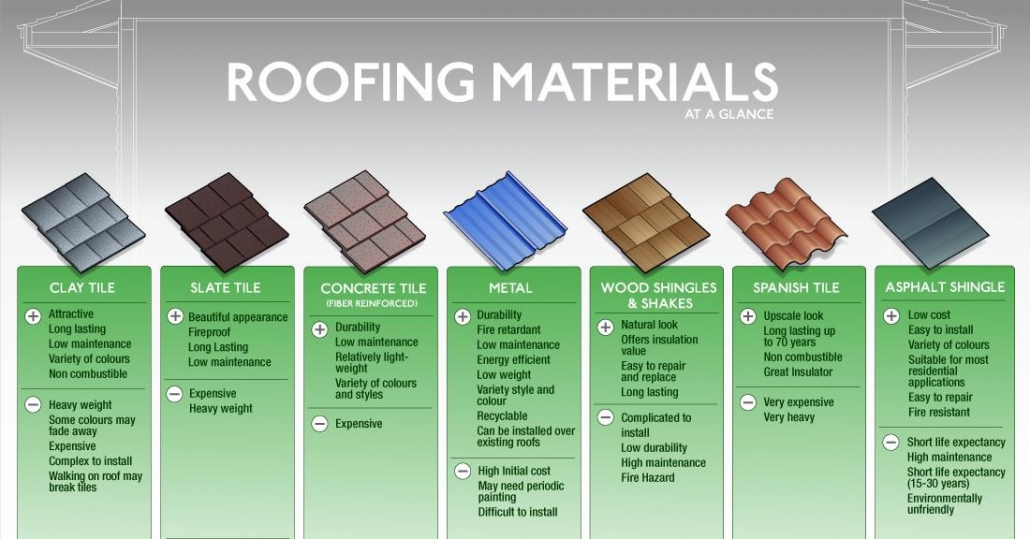

These energy efficient shingles save house owners money by lowering reliance on grid energy to cool the home. Wood roofings have declined in appeal in Arizona over time and the quality of products has actually seen a general reduction too. Still, lots of house owners like the aesthetic of a wood shingle roofing system.

The primary downside of wood roofs is that they are not fire resistant without the addition of unique chemicals. Because of this, some towns in Arizona have put restrictions on just how much a roof can be made of wood shake shingles. Shake roofings can also be attractive to termites if not properly treated.

Shake roofs are extremely ecologically friendly as they can be reused after usage for different things, such as mulch, or can be converted into pellets for wood burning ranges. Metal roofs have actually ended up being quite popular, especially for modern homes and business businesses. They provide an extremely enticing aesthetic that is both tidy and contemporary, as well as a long life.

Metal roofings are also great for fire resistance. Metal roofing systems tend to cost more than other roofing system choices. Metal roofs are susceptible to hail and heavy winds. And while beauty is always in the eye of the beholder, some individuals prefer the look of more conventional products such as sandcast, clay, and concrete tiles.

7 Most Common Roofing Materials

This helps homeowners keep energy costs down throughout the severe heat. And, naturally, the majority of metal is extremely recyclable. Tile roofs are the second most popular roof systems in Arizona. They can be made of clay, concrete and sandcast. Concrete tiles are usually more cost effective than clay, however tend to not last rather as long due to the underlayment being of lesser quality than what generally features clay or sandcast tiles.

Some Arizona tile roofs have actually even been even known to last up to 80 years! While tile roofs longevity might last the entire period of a homeowner's lifetime, the underlayment will need to be replaced every 25-35 years. Undamaged tiles can be re-installed and re-used. Tile roofings are also fireproof, resist rot, and the bulk of Arizona bugs.

: Tile roofings are rather heavy. Many roofing system structures are not strong enough to accommodate their weight. While the tiles themselves have the possible to last a life time, the underlayment will need to be replaced a number of times over the roofing system's lifetime. If you don't change the underlayment, leakages can happen and tiles can break.

Strolling on tiles can easily break them. Falling tree branches are also culprits. Because of tiles susceptibility of breaking, it's finest to have actually a certified roofing professional who is experienced at maneuvering on a tile roofing system perform any upkeep or repair. Tile roofs are one of the most environmentally friendly roof systems for four main reasons.

Choosing The Longest Lasting Roofing Material

Concrete and clay are mineral-based materials that can be quickly recycled and recycled. Concrete tile reabsorbs approximately 20% of co2 emissions. Energy efficient installation methods minimize heating & cooling expenses while reducing reliance on your regional electric utility. Polyurethane foam roofs are the most popular roof systems for flat roofs in Arizona and are extensively used for commercial roofing systems.

It's light-weight, resilient, and smooth. Foam roofings insulate your Arizona house, leading to a 7 15% decline in cooling expenses. Foam roofs are typically more expensive than more standard choices. Depending upon the type of coating you select, foam roofing has the possible to need more frequent maintenance than other type of roofings.

Considering https://raymondvnnx834.creatorlink.net/what-roofing-material-is-the-best that foam roofs have the ability to keep houses cool in the summer and warmer in the winter, foam roofs assist to lower energy costs and dependence on energy sourced energy, which is frequently produced from filthy, non-renewable sources. If you've been thinking about having your roofing system looked at, now's the time to act! Contact us through the button listed below to request your complimentary website assessment.

If you are thinking about re-roofing your home, your investment in roofing products has a direct connection to how long you can expect your new roofing system to last. The longest-lasting roofing items are inherently very resilient, such as concrete, clay or slate tiles and substantially outperform other natural items like wood shakes.

4 Best Flat Roof Materials

It's likewise important to keep in mind that local weather, the style of your building, amount of routine upkeep and the quality of the roofing items you acquire play essential functions in determining the life span of roof products. According to the National Association of House Builders, many roofing products are developed to last a minimum of numerous years under typical climate condition.

Expect to pay more for a premium, long-life product. Architectural asphalt-- These items last about 30 years on average. Wood shingles and shakes-- Wood roofing has a target life time of thirty years, however it can last a lot longer under moderate climate condition. Metal-- The International Association of Certified Home Inspectors jobs metal roof to last in between 40 to 80 years.

10 Best Roofing Materials For Warmer Climates

10 Best Roofing Materials For Warmer Climates

Slate, concrete and clay tiles-- Each of these products is ranked for a life span of 100 years or more by both the NAHB and NACHI. Longevity in a large part is associated with the cost and style of roofing materials. Asphalt shingles, which begin around $. 80 a square foot, are amongst the least-expensive property roof products.

https://www.youtube.com/embed/2Sw0AizzRro

Architectural shingles, which are typically about twice as thick (and heavy) as asphalt expenses around twice as much as routine asphalt shingles. Metal roof products are a premium home item, the Metal Roof Alliance states, and costs run about 2 to 3 times that of asphalt shingles. It's similar to tile or cedar shakes, however less expensive than slate.

How Long Can You Expect Your Roof Or Fridge To Last

Table of ContentsWhich Roofing Material Is Best? Top 5 Long-lasting MaterialsRoofing Buying GuideChoosing The Best Roof For Coastal HomesHow Long Can You Expect Your Roof Or Fridge To LastCool It: The 5 Best Roofing Materials For Hot Climates

roofingcalc.com/flat-roof-materials/ Here's the raw information on the expense of each kind of roofing system for the product and setup. In the majority of, there is a series of costs because both products and installers are readily available in good/better/best options. You get what you spend for! All costs listed below are noted on a per sq.

basis: Product Expense Installation Expense Total Cost $1. 00 $3. 50 $2. 50 $4. 50 $3. 50 $7. 50 $3. 00 $5. 50 $3. 50 $7. 00 $6. 50 $12. 50 $3. 00 $6. 00 $4. 00 $9. 00 $7. 00 $15. 00 (Clay & Concrete) $4. 00 $12. 00 $6.

00 $10. 00 $24. 00 (stone and composite) $4. 00 $15. 00 $5. 00 $10. 00 $9. 00 $25. 00 (based on % of solar tiles used) $25 $45 Here are short summaries to help you narrow your choices or choose a roof that will suit your home and your purposes.

What Is The Longest Lasting Roofing Material?

What Is The Longest Lasting Roofing Material?

Wood shingles and shakes: If you want a rustic yet handsome look, these are tough to beat. Hesitate if your roofing doesn't get much sun, and choose a knowledgeable professional because quality installation is crucial for resilience. Metal roofing: If you want elegant, eco-friendly roof that withstands snow and ice much better than the other products, metal is a great option.

The 5 Most Durable Roofing Materials

Clay, concrete or composite tiles: If a tile roofing system fits your house's architectural design, highly consider this product if it fits your budget plan. Clay is more expensive but lasts longer than concrete roof tile. Fiber cement composite tiles are a good middle-ground. Slate roofing: Upscale brick and stone houses just need a slate roof to make them truly unique.

Tesla solar tiles: These roofs are still largely untested outside the "laboratory," but reveal remarkable guarantee in theory. However, in practice, only a handful of these roofings have been installed given that the unveiling, leading us to think that Tesla solar tiles will likely go down in history as hyped-up vaporware.

roofingcalc.com/bipv-solar-shingles-cost/ If saving money were the objective, then hiring the least expensive labor would be the course to accomplishing it. However, that will likely turn out to be a mistake discovered when the roofing falls apart or fails to safeguard your house from the components. The much better route is to request price quotes from numerous certified and insured roof professionals that concentrate on the type of roof you want.

Then, get some referrals, drive by homes they roofed from 5-15 years ago to see how the roofing systems they have actually installed are holding up. Pro Tip: Ask about the experience of the team that will be installing your roof. This is the most total overview of these products and their expenses that http://juliushqna591.almoheet-travel.com/the-top-7-most-durable-long-lasting-roof-materials you'll find anywhere.

What Type Of Roof Lasts The Longest?

If the information was handy, please share it on social media, since every house owner will require a new roofing system eventually!.

Which Roofing Material Lasts The Longest

Which Roofing Material Lasts The Longest

A roofing system made from slate can last as long as 75150 years. One of the oldest roof materials, slate is also one of the most expensive. When it pertains to toughness, slate sticks out from the competitors. It's both fireproof and essentially invincible in many severe weather. Keep in mind that setup ought to be thoroughly executedslate tiles can crack under the weight of the average person.

Because of this, slate is an exceptionally sustainable roof product. Roofing waste (specifically asphalt shingle waste) accounts for 3% of all waste in garbage dumps. This is because house owners have to replace most roofing products every 3050 years. A roofing that could last 3 times as long as its competitors is better for the environment.

Lastly, since slate is among the densest roofing products on the market, it's exceptionally energy efficient, helping to control your home's internal temperature. Solar glass roofing should, incredibly, last for the life time of your house. Currently, although there are lots of producers that use solar panels for your roofing, Tesla is the only manufacturer that provides a solar glass roofing system.

Different Types Of Roofs That Increase Home Value

The energy effectiveness and the cost of solar glass roofing are inextricably linked. Although it's fairly pricey to install, you may certify for a tax credit to balance out the cost, depending on where you live. Also, while we calculate the energy performance of most roof products in terms of just how much energy they conserve, solar glass actually produces its own energy.

Which Roofing Material Lasts The Longest?

Which Roofing Material Lasts The Longest?

After repairing or changing your roof altogether, homeowners should consider protecting their financial investment by signing up for one of the very best home guarantees. Read our evaluation on Option Home Warranty, Select House Service Warranty, and The House Service Club as they're simply a few home service warranty companies that provide roofing system leak protection.

One concern we get a lot is, "Which roof product is the very best quality and lasts the longest in Arizona?" The response to this truly depends on what factors each house owner values most, whether it be looks, durability, general setup costs, or ease of upkeep. In brief, every roof system has its benefits, drawbacks, and environmentally friendly contributions.

Today's top roof products can quickly last for years when installed by a certified roof expert and effectively maintained. Even still, our serious Arizona heat, monsoon rains, and extreme UV exposure can damage even the very best systems. Taking appropriate care of your roof is critical. Setting up regular assessments and have any repairs made immediately to guarantee an optimum life expectancy and unexpected damage to your home or belongings.

How Long Does A Roof Last On Average? Solved!

https://www.youtube.com/embed/2Sw0AizzRro

Typically, 3-tab shingles are just a couple of dollars cheaper than the architectural shingles. 3-tab shingles are also a little thinner, which reduces their lifespan to the lower end of the expectancy range, depending on maintenance. Shingles are extremely economical alternative for any pitched roof. Shingles can also supply good fire resistance, with some types even able to combat against hail, wind, and mold growth.

Consider An Elastomeric Roof Coating

Table of ContentsTypes Of Liquid Applied Roof Waterproofing SystemsLiquid Applied Roofing SolutionsLiquid Applied Roofing SolutionsWhat Is Fluid-applied Commercial Flat Roofing?Liquid Applied Roofing Systems

Consist of membranes that are set up "in place" utilizing highly resilient, water based, waterproofing compounds enhanced with hard polyester fabrics and appeared with energy conserving reflective coverings. When set up the smooth monolithic system is difficult, flexible and resistant to the extremes of nature. We use Underwriters Laboratories (U.L.), FM Worldwide and independent screening labs to continuously check our Systems and Products to be sure they meet the stringent requirements these days's structure industry.

Western Colloid's Fluid Applied System's lead to a seamless finish making future examinations and upkeep easy. It likewise implies the roof can be resurfaced, consequently extending the life of the roofing indefinitely. Western Colloid's FARR system's can be applied over BUR, Modified Bitumen, Single Ply, Metal Roofing, Sprayed Polyurethane Foam and Gravel roofs.

Minimize energy and equipment expenses (beginning right away after the roofing is set up). Indefinitely extend or eliminate your requirement to re-roof or deal with significant repair work. Can be applied over your existing roofing with extremely little inconvenience. Will not impact employee/tenant productivity due to fumes. Can be shipped in bulk to the task site via our big fleet of tankers.

Liquid Applied Roofing 2020: Market Data And Insights

Liquid Applied Roofing 2020: Market Data And Insights

Liquid Applied Roofing 2020: Market Data And Insights

No toxic fumes or fire risk. Every product is backed by experience and efficiency. A number of our FARR systems have received UL Class A ratings. "Class A" roofing system assemblies have the best fire resistance. In addition, numerous of our systems have actually also gotten FM 4470 Class 1 approval. To attain this designation, the system undergoes strenuous testing for fire, hail damage, water leakage, and resistance to foot traffic.

During the middle of the 19th century, modern roofing as we understand it started to take shape when rag felt taken in tar was layered with hot-mopped tar and covered with gravel. Gradually, the tar was primarily replace by asphalt and the rag felt by fiberglass mat to develop the modern-day built-up roofing (BUR).

Liquid Applied Roofing Membranes

Liquid Applied Roofing Membranes

According to Jason Smith, senior R&D chemist at the Garland Business, cold-applied roof systems describe roofing systems that are adhered with an adhesive that doesn't need to be warmed prior to its application. They are utilized right out of the drum or pail and applied using a notched squeegee, or likewise by brush, spray, or roller, depending upon the viscosity of the product.

Liquid Applied Roofing Products

Lee Martucci, product manager at GAF, notes, "The technology was developed as a method to counter issues over possibly unsafe hot asphalt and fumes. When installing a roofing without the big, untidy hot kettles and fumes, the ecological and health concerns from the pubic minimize. Plus, contractors can set up the membrane systems without investing in expensive kettles: all they need is a squeegee." Cold-applied roof eliminates messy hot tar kettles and the associated fumes, which creates a safer jobsite and less inflammation for the structure occupants.

George Daisey, a research researcher at Dow Chemical https://5f7fcb4284b0d.site123.me/#section-5f8018218b9d9 Business, explains that cold-applied roofing system installations permit more secure handling of products, as there is no hot container to be hoisted onto the roofing system. Similarly, the application process eliminates the potential for burns or respiratory inflammation from hot fumes. Overall, cold-applied roofing system systems lead to a lower level of odor at the task website, which Martucci indicates can lead to fewer complaints from constructing occupants.

With much less equipment needed than in a hot-applied roof job, the general devices expenses are dramatically lower. Smith, at Garland, mentions that cold-applied roofing systems can be developed to have lower unstable organic compound (VOC) emissions, which can be of significance in VOC-restricted areas like California and much of the northeastern U.S.

Fluid Applied Roof Systems For Asphalt Roofs From Acrymax

Fluid Applied Roof Systems For Asphalt Roofs From Acrymax

Fluid Applied Roof Systems For Asphalt Roofs From Acrymax

According to Daisey, the term "cold-applied roof system" was originally utilized to explain a solvent-based built-up roofing that did not require heat to install. Today, the term has actually widened substantially as a range of innovations have actually been established to encompass the range of roof systems that do not require heating to be set up.

Cold-Process Built-Up Roofing uses heavyweight asphalt-impregnated fiberglass base sheets adhere in multiple plies with solvent-borne asphalt adhesives. The first sheet is generally mechanically connected to the substrate (usually insulation) and subsequent plies (generally 3 or four overall) are embedded in an application of adhesive at a rate usually in between 1.5 and 2.5 gallons per 100 sq.

Cold-process BUR utilizes solvent-based asphalt adhesives to adhere numerous layers of base sheet without heat. The membrane is then covered with aggregate. As soon as the waterproofing layer remains in place, the membrane is covered with an aggregate surface area or roofing coating. Customized Bitumen Roof is an adjustment of "torch-down" roofing. Modified bitumen roofings were generally set up utilizing a lp torch to melt the back of the sheet, creating a molten adhesive in which the roll might be embedded.

Fluid-applied Roofing Contractor

For obvious security factors, use of cold-applied roof has supplied an attractive option to making use of hot asphalt or open flame. These roofs normally have a mechanically attached base sheet, and one or 2 plies of customized bitumen membrane set up in bituminous adhesives. Smith describes these adhesives as "rubber-modified fibered solvated asphalt adhesives that dry by means of solvent evaporation." Martucci includes, "These buildings generally include asphalt/solvent blends used by a squeegee to adhere the membranes to the substrate of other membranes, although there are other innovations that can be used.

Monolithic Liquid-Applied Roofing blurs the line in between roof finish and roofing membrane system. Normally made from state-of-the-art polymeric resins such as urethanes, these roofs are used as a liquid and frequently need no strengthening material, treating to a difficult, rubber-like membrane. (See sidebar listed below). Naturally, as is the case with all roof technologies, there are particular downsides to making use of cold-applied roofing systems.

https://www.youtube.com/embed/ubKYOfLtEhI

Liquid-Applied Roofing is applied as a liquid and frequently needs no enhancing product, treating to a difficult, rubber-like membrane. Extra factors to consider include the flammability of cold-applied adhesives that are made with solvated asphalt, as well as the capacity for solvent odor to penetrate through occupied spaces through vents, simply as with the odors from hot-applied roofing systems.

TOPCOAT Liquid-Applied Roofing Systems

Table of ContentsAcrylic Or Silicone Roof Coatings For Your Commercial Roof?Elastomeric Roof CoatingsFrequently Asked Roof Coating QuestionsElastomeric Roof Coatings10-year Premium White Elastomeric Roof Coating

The aged measurements of the finest roofing finishings frequently beat those of rivals' new item measurements. That represents a serious distinction in coating quality and value with time. The perm aspect is the covering's resistance to moisture vapor travelling through it. A lower number shows less moisture can go through it.

You want a roofing finishing that repels water far from the roofing, rather than absorbing it into the roof material which can accelerate aging and wear and tear of the roof itself. Peel adhesion determines the capability of the covering system to stay adhered to the roofing system surface area under adverse conditions. If your roofing system finish does not remain firmly attached, then it can't correctly safeguard your roofing.

Reflectivity procedures how much solar heat is shown far from the roof by the finish. A cool, reflective roofing system surface allows all developing elements to work more effectively and reduces maintenance requirements and early roofing system failure caused by UV damage and thermal shock. When choosing the best elastomeric finishing choice for your roof, there's more to consider than just the finishing's particular homes.

White Elastomeric Roof Coating– 10 Year Protection

Comparing performance between brands can assist you decide which choice is best for your requirements. The chart listed below programs how Topps Seal compares in efficiency against other alternatives based upon the ASTM Miami-Dade requirement on some of the essential homes for an elastomeric roof covering. The American Society for Screening Materials (ASTM) supplies national standards for testing treatments of elastomeric roofing coverings.

This is an exceptional starting point for asking concerns of what you desire utilized for your job. Miami-Dade County, Florida, assigns to roofing system finish products what they think about to be minimal requirements for usage in this difficult environment. In order to be approved for lawful usage in the county, a product must undergo testing by a federal government authorized 3rd party lab to guarantee that it meets the county's minimum standards (as shown under 100% Acrylic in the chart above).

What Is & How To Apply Elastomeric Roof Coating

What Is & How To Apply Elastomeric Roof Coating

They worry that when evaluating a roof finishing. Having great outcomes on simply one component is not sufficient to use for selection requirements. Picking the very best roofing finishing can have major long-term implications, so at Topps, we really suggest that you take your questions a few steps even more than simply the ASTM requirements, and concentrate on the entire bundle and how it might impact your results.

How Do You Apply Elastomeric Roof Coating

Think about genuine physical residential or commercial properties over the producer's claims. Only the former will provide you with maximum benefits. Make sure that the product you choose is the most preferable choice for the series of conditions in your environment. Selecting a finish that can withstand any climate likely will be of benefit to you.

Third-party independent screening, beyond requirements used just for marketing functions, can be important to you without costing you more. Due To The Fact That Miami-Dade County Florida has what most consider to be the gold standard set of requirements for roofing system covering characteristics, where passage is required for legal use in those locations, it can be an exceptional starting criteria.

The expense difference for higher quality products, if there is one, will be negligible in the scheme of things. In addition to having requirements for efficiency when brand-new in the laboratory, Miami-Dade Country approved products likewise require roofing system coverings to be evaluated when they are aged. After a finish is aged, you can get a much better understanding of the rate at which it deteriorates and changes.

Myths, Facts, And The Truth About Silicone And Elastomeric

Their reporting shows you how it compares. Ask your vendor about making use of their items throughout numerous conditions, but likewise Miami-Dade standards. Are they authorized for Miami-Dade county? Can they offer you with the results of tests conducted on their aged products after exposure to the weather condition? This information is important to discovering the best roofing covering item readily available.

Elastomeric Roof Coating

Elastomeric Roof Coating

Prevent products having the weakest link in the chain among essential physical homes. Last, but not least, the ability of your roofing coating to provide a cool roof is incredibly essential. UV rays and thermal shock can cause serious damage and deterioration to a roofing system. A white elastomeric roofing system coating, having actually proven solar reliable homes, provides defense against heat and therefore can likewise assist http://waylonvune841.raidersfanteamshop.com/the-pros-cons-for-elastomeric-paint-1 to drastically lower the energy required to cool your structure.

Once again, this is one element among a number that can be valuable to you. So think about the whole package. If your white roofing system finish degrades rapidly gradually it loses the energy and cooling benefits it at first provided. Consider those rather who also use CRRC Cool Roofing Rating Council for third-party verification on cool roofing retention in time if this is necessary to you.

Elastomeric Roof Coatings

You do not want it to be the weak spot in your "value chain". CRRC reports this. Outside of some highly specialized locations, it can be hard to find in-depth evaluations of elastomeric finish products. How do you choose which items hold up finest on metal roofings? Or which sealants are best for your roofing system conditions? One method to examine an elastomeric covering product is to evaluate 3rd celebration independent reviews such as Cool Roofing System Ranking Council, MiamiDade County (approval carries confirmation), and Energy Star.

Check to see that the maker really recommends their items for your roofing system type and make certain all items suggested for your project are included. A professional making a statement that in their viewpoint only some products are needed, is simply thattheir viewpoint. A qualified professional providing a guarantee or pledge will have at least as many years' experience supporting their claims or will follow standards of a manufacturer who does.

https://www.youtube.com/embed/9ecl0RV3PBQ

You can examine some examples of Topps elastomeric roofing system coating alternatives here. You might also gain from checking out the experiences of others who have actually used specific products themselves. There are few better sources of item info than qualified independent test results confirming the outcomes, together with customers who have actually used elastomeric roofing system finishings whose conditions correspond yours.

6 Best Roofing Materials Ranked By Durability And Cost

Table of ContentsChoosing The Longest Lasting Roofing MaterialThe Pros & Cons Of Different Roofing MaterialsRoofs And Roofing Materials Comparisons

It's not all about the charm, after all. It is likewise unequalled in the durability department. Now that you have found the most lasting roofing materials, let now talk about things that can help them reach their max capacity. Longevity can vary. This is due to the fact that of the several aspects that impact roofing products' ability to lengthen their life service.

There are roofing products that are proven to carry out well even in the middle of the harshest weather. To know whether a roof product is premium or not, you need professional https://diigo.com/0inbyd viewpoints from trusted roof experts. Depending on where you lie, there are roof that can flourish much better in certain environments or weather.

Roofing Materials

Roofing Materials

For example, even if you have a lasting roofing product, consistent UV ray direct exposure might accelerate its degeneration. Natural incidents run out out of our control as people but we can always pick to secure our residential or commercial properties with the assistance of professional upkeep procedures. We typically say this and we'll restate it again. Some property owners minimize the role of upkeep because they seem like their roof can survive on its own. False. You need to assist your roofing reach its maximum level by ensuring that you attend to any prospective or current problem the moment you find out about it. There are tons of roofing products that are readily available today.

Best Roofing Materials For Homes 2020: Material Costs, Plus

Thanks to technology, we'll always be able to discover something that would fit our own requirements, style choices, and even our long-term priorities. Always remember, durability is very crucial. But there are other factors to include in the formula such as expense, unfavorable qualities, etc. Desire to understand what roofing products would work for you?The team is always available for a consultation.

Therefore, we motivate you to talk to our roofing specialists to find out what roof materials would fit your needs. Call us at and receive a.

The lifespan of your roofing system will depend on a myriad of elements, such as its style, ecological conditions, quality of installation, how to repair your roof and direct exposure to the elements. Likewise, taking correct care of your roof with routine examinations and prompt repairs when needed can assist you get the most out of your roof.

What Are The Best Roofing Shingles In 2020?

Roofs And Roofing Materials Comparisons

Roofs And Roofing Materials Comparisons

If you are looking to replace your roofing or install a roofing system for a new building and construction project, it is essential to consider the numerous life-spans of roof products when making your decision.: 15 to twenty years: 10 to 30 years: 50+ years: 50+ years: 50+ years: 25+ years -Up roofings: 25-30 years -Ply: 30+ years The typical roof will last around 20 years, though correctly kept roofings can last far longer than their service warranties recommend.

In addition to picking the right type, it is essential to select a brand of roof material that is known for being top quality. roof coating cost For example, while wood shingles in general might be estimated to last from 15 to twenty years, going with low-grade shingles to save a couple of bucks will likely shave a few years off of its life.

https://www.youtube.com/embed/fGG41JWyfno

It is equally important to make certain your roofing is installed by a respectable roofing company that adheres to all structure and safety codes.: Incorrect installation can and will void your maker's service warranty. At Lyons Roofing, our Phoenix and Tucson roofing professionals have actually gone far for ourselves due to our unwavering devotion to quality both in workmanship and in client service.

Advancements in Fluid Applied Membranes for Roofing

Table of ContentsLiquid-applied Waterproofing Roofing ProductsTopcoat Liquid-applied Roofing SystemsColor Liquid-applied RoofingKm Coatings: Commercial Grade Liquid-applied Roof SystemsParapro Pmma Liquid-applied Roofing Systems

Consist of membranes that are set up "in place" utilizing extremely resilient, water based, waterproofing substances reinforced with tough polyester fabrics and surfaced with energy conserving reflective coverings. When set up the smooth monolithic system is difficult, flexible and resistant to the extremes of nature. We use Underwriters Laboratories (U.L.), FM Global and independent testing laboratories to continually check our Systems and Products to be sure they satisfy the stringent requirements these days's building market.

Western Colloid's Fluid Applied System's lead to a smooth finish making future examinations and upkeep simple. It also suggests the roofing system can be resurfaced, thus extending the life of the roofing forever. Western Colloid's FARR system's can be used over BUR, Modified Bitumen, Single Ply, Metal Roof, Sprayed Polyurethane Foam and Gravel roofing systems.

Save on energy and devices expenses (starting right away after the roofing system is set up). Forever extend or remove your need to re-roof or deal with significant repairs. Can be applied over your existing roofing with very little inconvenience. Will not affect employee/tenant efficiency due to fumes. Can be delivered in bulk to the job site via our large fleet of tankers.

Liquid-applied Membrane For Roofs

Fluid Applied Roofing Systems

Fluid Applied Roofing Systems

No poisonous fumes or fire hazard. Every item is backed by experience and performance. Numerous of our FARR systems have received UL Class A scores. "Class A" roof assemblies have the biggest fire resistance. Furthermore, numerous of our systems have likewise received FM 4470 Class 1 approval. To achieve this designation, the system goes through strenuous screening for fire, hail damage, water leak, and resistance to foot traffic.

Throughout the middle of the 19th century, modern-day roof as we understand it began to take shape when rag felt taken in tar was layered with hot-mopped tar and covered with gravel. Over time, the tar was mainly replace by asphalt and the rag felt by fiberglass mat to create the modern-day built-up roof (BUR).

All About Liquid Applied Silicone Membrane Roofing

All About Liquid Applied Silicone Membrane Roofing

According to Jason Smith, senior R&D chemist at the Garland Business, cold-applied roofing system systems refer to roofings that are http://zanepvfu400.iamarrows.com/liquid-applied-roofing adhered with an adhesive that does not need to be warmed prior to its application. They are utilized ideal out of the drum or pail and used utilizing a notched squeegee, or also by brush, spray, or roller, depending on the viscosity of the item.

Paints, Coatings, Liquid-applied Membranes In Roofing

Lee Martucci, item supervisor at GAF, notes, "The technology was developed as a way to counter concerns over possibly unsafe hot asphalt and fumes. When installing a roofing system without the huge, messy hot kettles and fumes, the ecological and health concerns from the pubic decrease. Plus, specialists can install the membrane systems without investing in expensive kettles: all they require is a squeegee." Cold-applied roof eliminates untidy hot tar roofing repair contractors kettles and the associated flat roof leak repair fumes, which develops a safer jobsite and less inflammation for the building occupants.

George Daisey, a research study scientist at Dow Chemical Company, explains that cold-applied roof installations allow for safer handling of products, as there is no hot container to be raised onto the roof. Similarly, the application procedure gets rid of the capacity for burns or breathing inflammation from hot fumes. Overall, cold-applied roof systems lead to a lower level of smell at the task website, which Martucci suggests can result in fewer problems from developing occupants.

With much less equipment required than in a hot-applied roofing task, the total devices costs are significantly lower. Smith, at Garland, points out that cold-applied roofing system systems can be formulated to have lower unpredictable natural substance (VOC) emissions, which can be of significance in VOC-restricted locations like California and much of the northeastern U.S.

Liquid Applied Roofing Membranes

Product Evaluation

Product Evaluation

According to Daisey, the term "cold-applied roofing system" was initially used to describe a solvent-based built-up roofing that did not need heat to set up. Today, the term has expanded substantially as a range of innovations have actually been established to incorporate the range of roof that do not require heating to be installed.

Cold-Process Built-Up Roof uses heavyweight asphalt-impregnated fiberglass base sheets adhere in multiple plies with solvent-borne asphalt adhesives. The first sheet is usually mechanically connected to the substrate (normally insulation) and subsequent plies (usually three or 4 total) are embedded in an application of adhesive at a rate usually between 1.5 and 2.5 gallons per 100 sq.

Cold-process BUR uses solvent-based asphalt adhesives to adhere numerous layers of base sheet without heat. The membrane is then covered with aggregate. As soon as the waterproofing layer remains in place, the membrane is covered with an aggregate surface area or roofing system covering. Customized Bitumen Roof is an adjustment of "torch-down" roof. Customized bitumen roofs were typically installed using a gas torch to melt the back of the sheet, producing a molten adhesive in which the roll could be embedded.

Paints, Coatings, Liquid-applied Membranes In Roofing

For apparent safety reasons, use of cold-applied roofing has supplied an attractive option to the usage of hot asphalt or open flame. These roofing systems usually have actually a mechanically attached base sheet, and a couple of plies of customized bitumen membrane set up in bituminous adhesives. Smith describes these adhesives as "rubber-modified fibered solvated asphalt adhesives that dry through solvent evaporation." Martucci adds, "These constructions generally include asphalt/solvent blends used by a squeegee to adhere the membranes to the substrate of other membranes, although there are other innovations that can be used.

Monolithic Liquid-Applied Roofing blurs the line in between roofing system covering and roofing system membrane system. Normally made of modern polymeric resins such as urethanes, these roofing systems are applied as a liquid and often need no reinforcing product, curing to a tough, rubber-like membrane. (See sidebar listed below). Naturally, as is the case with all roofing innovations, there are particular disadvantages to using cold-applied roofing system systems.

https://www.youtube.com/embed/zHn_IUEgUos

Liquid-Applied Roofing is used as a liquid and often requires no enhancing product, curing to a tough, rubber-like membrane. Extra factors to consider include the flammability of cold-applied adhesives that are made with solvated asphalt, along with the potential for solvent smell to penetrate through inhabited areas through vents, just as with the odors from hot-applied roof systems.

6 Best Roofing Materials Ranked By Durability And Cost

Table of ContentsList Of Commercially Available Roofing Materials3 Most Promising And Long-lasting Roofing Materials InLooking For A Lifetime RoofWhat Roofing Material Is The Best?

What Is The Longest Lasting Roofing Material?

What Is The Longest Lasting Roofing Material?

These energy effective shingles conserve house owners cash by decreasing reliance on grid energy to cool http://rylanbnvv387.tearosediner.net/types-of-roofing-to-choose-from the house. Wood roofings have declined in popularity in Arizona with time and the quality of materials has actually seen a general decrease as well. Still, lots of house owners like the aesthetic of a wood shingle roof.

The primary drawback of wood roofs is that they are not fire resistant without the addition of unique chemicals. Due to the fact that of this, some municipalities in Arizona have put restrictions on how much a roof can be made of wood shake shingles. Shake roofings can likewise be appealing to termites if not effectively dealt with.

Shake roofings are really environmentally friendly as they can be recycled after use for various things, such as mulch, or can be transformed into pellets for wood burning ranges. Metal roofings have actually become rather popular, specifically for modern houses and business organizations. They provide an extremely attractive visual that is both clean and modern, as well as a long life.

What Type Of Roofing Materials Last The Longest

What Type Of Roofing Materials Last The Longest

Metal roofs are also fantastic for fire resistance. Metal roofs tend to cost more than other roof alternatives. Metal roofings are prone to hail and heavy winds. And while charm is always in the eye of the beholder, some people choose the look of more traditional products such as sandcast, clay, and concrete tiles.

What Is The Longest Lasting Roofing Material?

This helps house owners keep energy expenses down during the extreme heat. And, of course, the majority of metal is highly recyclable. Tile roofings are the second most popular roof systems in Arizona. They can be made of clay, concrete and sandcast. Concrete tiles are usually more cost effective than clay, but tend to not last rather as long due to the underlayment being of lower quality than what typically features clay or sandcast tiles.

Some Arizona tile roofs have even been even understood to last up to 80 years! While tile roofings longevity may last the whole period of a house owner's life time, the underlayment will require to be replaced every 25-35 years. Undamaged tiles can be re-installed and re-used. Tile roofing systems are also fire-resistant, resist rot, and the bulk of Arizona bugs.

: Tile roofing systems are rather heavy. Numerous roofing structures are not strong enough to accommodate their weight. While the tiles themselves have the prospective to last a lifetime, the underlayment will require to be replaced a number of times over the roofing's lifetime. If you don't replace the underlayment, leakages can occur and tiles can break.

Walking on tiles can quickly break them. Falling tree branches are also culprits. Because of tiles susceptibility of breaking, it's finest to have actually a qualified roof specialist who is knowledgeable at maneuvering on a tile roofing carry out any maintenance or repair work. Tile roofs are one of the most environmentally friendly roof systems for four main factors.

The 5 Most Durable Roofing Materials

Concrete and clay are mineral-based materials that can be easily recycled and reused. Concrete tile reabsorbs as much as 20% of co2 emissions. Energy efficient installation strategies decrease heating and cooling expenses while reducing reliance on your regional electrical utility. Polyurethane foam roofings are the most popular roof systems for flat roofing systems in Arizona and are commonly utilized for commercial roof systems.

It's lightweight, durable, and smooth. Foam roofings insulate your Arizona house, causing a 7 15% reduction in cooling expenses. Foam roofing systems are usually more pricey than more traditional choices. Depending on the kind of finish you pick, foam roofing has the potential to require more frequent upkeep than other sort of roofings.

Since foam roofs have the ability to keep homes cool in the summer and warmer in the winter season, foam roofing systems assist to lower energy expenses and reliance on utility sourced energy, which is typically produced from dirty, non-renewable sources. If you've been considering having your roof looked at, now's the time to act! Contact us through the button listed below to request your complimentary website evaluation.

If you are considering re-roofing your home, your financial investment in roof products has a direct connection to how long you can expect your new roof to last. The longest-lasting roofing items are naturally incredibly durable, such as concrete, clay or slate tiles and significantly outperform other roof truss repair natural items like wood shakes.

7 Most Common Roofing Materials

It's likewise important to bear in mind that local weather conditions, the style of your structure, quantity of routine upkeep and the quality of the roofing items you acquire play crucial functions in determining the life expectancy of roofing products. According to the National Association of House Builders, many roof products are created to last a minimum of several years under typical climate condition.

Anticipate to pay more for a premium, long-life item. Architectural asphalt-- These items last about 30 years usually. Wood shingles and shakes-- Wood roof has a target lifetime of thirty years, however it roof gutter repair can last much longer under moderate weather condition conditions. Metal-- The International Association of Licensed House Inspectors tasks metal roofing to last in between 40 to 80 years.

What Is The Longest Lasting Roofing Material?

What Is The Longest Lasting Roofing Material?

Slate, concrete and clay tiles-- Each of these items is ranked for a life span of 100 years or more by both the NAHB and NACHI. Durability in a big part is connected to the expense and style of roof materials. Asphalt shingles, which begin around $. 80 a square foot, are among the least-expensive domestic roof products.

https://www.youtube.com/embed/EORCFDJOZOY

Architectural shingles, which are generally about two times as thick (and heavy) as asphalt expenses around twice as much as regular asphalt shingles. Metal roofing materials are a premium home product, the Metal Roof Alliance says, and costs run about 2 to 3 times that of asphalt shingles. It's comparable to tile or cedar shakes, but less costly than slate.

Advancements in Fluid Applied Membranes for Roofing

Table of ContentsWhat Is An Elastomeric Roof Coating?10-year Premium White Elastomeric Roof CoatingElastomeric Roof Coating Systems Can Last 20 Plus YearsElastomeric 7 Year Elastomeric Roof CoatingHow-to: Apply Cool Roof Coating

The aged measurements of the very best roof finishings frequently beat those of rivals' new item measurements. That represents a major difference in coating quality and worth in time. The perm aspect is the covering's resistance to wetness vapor passing through it. A lower number reveals less moisture can travel through it.

You desire a roofing covering that pushes back water away from the roofing system, instead of absorbing it into the roof material which can speed up aging and deterioration of the roof itself. Peel adhesion determines the ability of the finishing system to remain adhered to the roof surface under adverse conditions. If your roof covering doesn't remain firmly connected, then it can't properly protect your roofing.

Reflectivity steps just how much solar heat is reflected far from the roofing system by the coating. A cool, reflective roof surface area enables all constructing components to work more efficiently and decreases upkeep needs and early roof failure triggered by UV damage and thermal shock. When picking the right elastomeric finish choice for your roofing, there's more to think about than just the finishing's particular properties.

Can You Walk On Elastomeric Roof Coating?

Comparing performance between brands can help you choose which choice is best for your needs. The chart listed below shows how Topps Seal compares https://augustqtds683.shutterfly.com/22 in efficiency versus other alternatives based upon the ASTM Miami-Dade requirement on some of the crucial residential or commercial properties for an elastomeric roof coating. The American Society for Testing Materials (ASTM) products national requirements for screening treatments of elastomeric roofing system coatings.

This is an outstanding beginning point for asking concerns of what you desire used for your project. Miami-Dade County, Florida, assigns to roofing system covering products what they consider to be minimal requirements for usage in this challenging environment. In order to be authorized for legal use in the county, a product must undergo screening by a government approved 3rd celebration laboratory to ensure that it fulfills the county's minimum requirements (as shown under 100% Acrylic in the chart above).

What Is & How To Apply Elastomeric Roof Coating

What Is & How To Apply Elastomeric Roof Coating

They worry that when evaluating a roof covering. Having good outcomes on just one element is inadequate to utilize for choice requirements. Picking the best roofing system covering can have serious long-lasting implications, so at Topps, we really recommend that you take your concerns a few steps even more than simply the ASTM standards, and concentrate on the entire package and how it might impact your results.

Butyl Elastomeric Roof Coating Explained

Think about genuine physical residential or commercial properties over the manufacturer's claims. Only the previous will provide you with maximum advantages. Make sure that the product you choose is the most desirable alternative for the variety of conditions in your climate. Choosing a coating that can stand up to any climate likely will be of advantage to you.

Third-party independent testing, beyond standards used only for marketing purposes, can be indispensable to you without costing you more. Because Miami-Dade County Florida has what most consider to be the gold requirement set of requirements for roofing system coating attributes, where passage is required for legal usage in those locations, it can be an excellent beginning criteria.

The cost distinction for greater quality items, if there is one, will be negligible in the scheme of things. In addition to having requirements for efficiency when brand-new in the laboratory, Miami-Dade Nation approved products also need roofing system coatings to be tested when they are aged. After a finish is aged, you can get a better understanding of the rate at which it weakens and alters.

Sealing A Roof With A Roof Coating

Their reporting reveals you how it compares. Ask your supplier about making use of how much does it cost to reseal a roof their products across numerous conditions, but also Miami-Dade requirements. Are they approved for Miami-Dade county? Can they offer you with the outcomes of tests conducted on their aged products after exposure to the weather condition? This details is important to discovering the absolute best roof covering product offered.

Duck Coat Roof Coating – Duck Coat

Duck Coat Roof Coating – Duck Coat

Avoid items having the weakest link in the chain among essential physical properties. Last, but not least, the ability of your roofing finish to provide a cool roofing system is extremely important. UV rays and thermal shock can trigger severe damage and degeneration to a roofing system. A white elastomeric roofing finish, having actually shown solar efficient homes, provides security against heat and therefore can likewise assist to significantly reduce the energy needed to cool your structure.

Again, this is one element among a number that can be valuable to you. So think about the whole plan. If your white roofing system coating deteriorates rapidly with time it loses the energy and cooling advantages it initially provided. Think about those instead who also use CRRC Cool Roof Ranking Council for third-party confirmation on cool roofing retention over time if this is necessary to you.

What Are Elastomeric Coating And How Are They Used

You do not desire it to be the weak link in your "value chain". CRRC reports this. Beyond some extremely specialized venues, how much is a roof leak repair it can be challenging to find comprehensive evaluations of elastomeric coating products. How do you decide which items hold up finest on metal roofs? Or which sealants are best for your roofing conditions? One way to examine an elastomeric covering item is to review 3rd party independent evaluations such as Cool Roofing Score Council, MiamiDade County (approval brings verification), and Energy Star.

Check to see that the maker in fact advises their items for your roof type and be sure all items recommended for your task are consisted of. A contractor making a statement that in their opinion only some items are required, is just thattheir opinion. A certified contractor providing a warranty or guarantee will have at least as many years' experience supporting their claims or will follow guidelines of a manufacturer who does.

https://www.youtube.com/embed/WkoCPvAcAYE

You can examine some examples of Topps elastomeric roofing system covering choices here. You may also benefit from reading about the experiences of others who have actually utilized particular items themselves. There are few much better sources of product info than certified independent test results verifying the results, together with customers who have utilized elastomeric roof finishings whose conditions are similar to yours.

Why Armor Roof Coatings Are The Best

Table of ContentsElastomeric Roof Coating Contractors Battle CreekHow Long Do Roof Coatings Last?Which Roof Coating Performs Best?How-to: Apply Cool Roof CoatingSealing A Roof With A Roof CoatingRoof Sealants & Coating At Ace Hardware

Can You Walk On Elastomeric Roof Coating?

Can You Walk On Elastomeric Roof Coating?

Some less-than-reputable roofing specialists are informing customers around St. Louis that silicone industrial roof finishings will last 50 years. However, our experience and the research shows otherwise. Our group sees silicone roofing finishes lose their effectiveness on a regular basis. Reality: The typical silicone roofing system covering lasts around * X number of * years.

There are several instances where we saw silicone roofing system coatings jeopardize their quality within a matter of years due to normal wear and tear. Silicone has some serious disadvantages to think about: The initial setup expenses can be much higher than other industrial roofing finishes a silicon-based business roofing covering is frequently at least twice as pricey as an acrylic-based commercial roofing system coating.

If you need to use another coat, you have to use a suitable silicone-based finishing. Silicone roof coatings are untidy to install and repair. If you have to remove it, silicone roof finishings are stubborn! In time silicone tends to pull back from roofing edges and agreement into a curl. This means exposed roofing substrates that are no longer waterproof or moisture-proof.

How Long Do Elastomeric Roof Coatings Last?

" It doesn't matter, simply put enough silicone and you'll never ever have to fret about ponding ever once again!" In reality, silicone roofing system coatings have one of the greatest vapor permeability rates in the industrial roofing industry, typically because it is improperly used. (Source) Do silicone roofing coverings work to fix ponding concerns? Definitely, they do work, but they should be expertly applied by a skilled and comprehensive business roofer.

Again, numerous contractors believing silicone roofing system coatings are the 'silicone silver bullet'. With this myopic method to industrial roofing system repair and maintenance, it's easy not to account for this sixty-four-thousand-dollar question: will that component abide by my new silicone roofing finish? Regrettably, silicone is highly resistant to any other product sticking to its surface area once the applied substance finishes curing.

For instance, if you have an exposed opening in your roof surface area, simply using spray foam to reach the silicone covering usually does not work. The spray foam (SPF) will not adhere to the silicone surface area. You will require to eliminate the existing silicone so the foam will stick.

Kool Seal Premium 10 Year Elastomeric Roof Coating

Silicone is typically a one-pass product so you minimize guy hours with using it. The reason is silicone roof finishings normally have a higher volume of solid products inside their composition. This allows us to apply a single coat without stressing over coverage and quality. While setup (and clean-up!) is untidy for silicone roof coverings, it is among the most convenient roof finishes to set up.

Silicone roof coverings are likewise mostly great for the environment given that they're solvent-free and have very little VOC levels. Silicone roofing finishings tend to weather much better than a lot of any other roofing system coating. https://dcroofingarizona.wordpress.com/2020/08/10/what-kind-of-roof-lasts-the-longest-q-a/ Because they are moisture-cured and solids-based, silicone can be applied at practically any temperature level and often eliminate any need for guide.

Simply since we love a product doesn't suggest it lacks its reasonable share of flaws, reports, and even flat-out myths! Acrylic is strong, however it can't be strong enough to endure foot traffic on flat roofings, right? With acrylics normally being thinner than silicones, this is a simple myth to believe.

Fluid-applied Roof Coatings

As an example, our R&A Contracting team utilizes Lapolla Industries Thermo-Flex Acrylic Base roofing system coating (read: Elastomeric) that surpasses efficiency standards. It carries an industry-leading UV protection that deflects the sun's damaging UV rays and safeguards your Elastomeric is extremely popular for commercial roofing professionals since of its density, flexibility, and durability.

Nevertheless, this is an inexpedient option. R&A Contracting usages spray polyurethane foam, or SPF as it's fondly called, to elevate low roofing levels. The spray foam expands to fill and level the depression in the roofing surface. The spray foam abides by essentially any roof surface area to develop a seamless covering over the depression.

![]() How Much Does It Cost To Coat Or Seal A Roof?

How Much Does It Cost To Coat Or Seal A Roof?

This indicates your previously popular ponding spot is now on level with the rest of the surrounding roofing. High winds, severe temperature levels, snow, ice, and rain can place a beating on any roof surface. How do we understand if elastomerics are up for the task? Truth: Elastomerics are monolithic, adhesive, and designed to handle Given that elastomerics are flexible and acrylic-based, they adhere well to essentially any roof substrate.

Consider An Elastomeric Roof Coating

In reality, elastomerics are a few of the most popular roofing finishings to stand up to hurricane-force winds and debris in the Gulf Coast. Elastomeric roof coverings need to be applied in at least two applications, often 3 in specific circumstances. Elastomerics are breathable, so they do let some wetness particles through their material but only a very little amount.

Elastomerics are understood for maintaining roofing systems from the long-lasting destructive effects of thermal heat. When it concerns St. Louis services, we have actually got you covered! Our R&A Contracting team works with industrial building owners to discover the very best industrial roofing service for each scenario. We can work with you to check your roof, identify potential issue locations, and develop a customized roofing system upkeep and repair program to keep your roof healthy and strong for years to come.

It's complimentary and we invite you to ask any concerns you may have about your roof. Follow this link to send us a message and begin a discussion today!.

Butyl Elastomeric Roof Coating Explained

?.!!. Flat rowhouse roofs were coated with a white elastomeric substance that reflects heat and keeps interiors cool. The covering was produced, I think, by Rohm & Hass (now Dow Chemical), and, at the time, featured a 10-year guarantee, according to the individuals at the agency.

https://www.youtube.com/embed/5bVnqMi_4Bk

Today's blog post covers the life span of industrial roof coverings. When the first acrylic roofing system coating was presented in the 1970s, the commercial roof industry had some dramatic modifications. Public interest in energy-efficient roof started strengthening. Roof coatings caused the launch of the cool roof system and helped led the way for companies such as ENERGY STAR, the Cool Roofs Ranking Council, and others to acquire traction as recognized accreditation celebrations of energy-efficient roof.

We Are Metal Roofing Experts

Table of ContentsThe Best Roof Types For This AreaBest Roofing Materials For Homes 2020: Material Costs, Plus5 Reasons Why A Metal Roof Is The Perfect Roof17 Types Of Roof Shingles - The Complete Guide

What Type Of Roof Lasts The Longest?

What Type Of Roof Lasts The Longest?

Average costs for installing this roofing system are about $2. 25 per square foot, for a total average cost of approximately However presuming that this roof will likely require to be replaced maybe 12 times over 100 years, total costs over this duration, in today's dollars, can be as high as.

Typically used on roofing systems that are flat or with an extremely minor pitch, BUR roofIt is fire-resistant and affordable, however the roof is unpleasant and foul-smelling to set up. BUR roofing systems normally last from 20 to 30 years. Taking full advantage of the life expectancy of a built-up roofing system is accomplished by regular maintenance, and by keeping particles off the roof to avoid deterioration of the surface.

On a 2,000 square foot home with a roofing system very near that square video, average professional installation costs aboutAssuming that this roof will need to be replaced about four times over a 100 year period, average roofing costs in today's dollars have to do with Composite shingle roof is the most popular of all roof materials, found on more than 80 percent of all houses.

Top 6 Roofing Materials

Top 6 Roofing Materials

The huge appeal of shingles owes to the relatively low expense, easy installation, and good life span. These roofings are normally set up by professional crews, but installation is not out of reach for a knowledgeable DIYer. Composite asphalt shingles can be expected to last 15 to 40 years, depending on the quality of the products picked.

Most shingle roofing produces use a range of items in various weights and various life expectancies. Makers like Owens Corning, GAF, or Certainteed include accordingly high-end guarantees pushing a half-century. Take full advantage of the life-span of asphalt shingle roofs by preventing inexpensive shingles and preventing strolling on them. Keep them devoid of moss, and never ever power clean an asphalt shingle roofing system.

What Type Of Roof Last The Longest?

Presuming that a 2,000 square foot home with a typical roofing slopes has a roofing square video footage of about 2,200 square feet, that roofing system averages about for expert installation. Assuming this roofing might be changed 3 to 4 times, an asphalt shingle roof will cost, in today's dollars, Considering that a typical house owner hardly ever lives in a home for more than 30 or 40 years, during which they may reroof only when, asphalt shingles make for a relatively cost-effective roofing material from the majority of people.

They make for a very appealing roofing system but are tricky to set up and not appropriate for the majority of DIYers. Know that growing fire risks in some areas has caused legal limitations on making use of wood roof materials. They are not a great option in any location where there are seasonal wildfire hazards.

Thoroughly preserved, wood shingle roofs can last for 50 years. To extend the life of a wood shingle roofing, make certain to change split and split shingles right away, and keep the roofing system without moss. Wood shingles are more expensive than asphalt shingles, costing in between $6. 50 and $11. 00 per square foot, installed.

Presuming this roofing system will need to be changed at least three or four times over a century, costs can be as high as determined in today's dollars. steverts/ Getty Images Wood shakes are a thicker material than wood shingles, and they can be expected to stand much better than wood shingles to weather and UV rays.

Like wood shingles, shakes may be restricted in regions where wildfires are a known danger. Wood shake roofing systems can be expected to last 35 to 40 years, though longer life is not uncommon. To maximize life-span, you do require to child them and practice proper upkeep. There is no "set it and forget it" alternative for any wood roof material.

Best Roofing Materials To Top Off Your House In 2020

Get rid of moss. Change split shakes right away. Change curled, cupped, or split shakes right away. Both the materials and installation are more pricey for shakes than for wood shingles. You can usually depend on shakes having to do with 50 percent more expensive than shingles. Based on a presumption of $13 per square foot, a 2,000 square foot home with 2,200 in sloped roofing square video will cost to https://dcroofingarizona.blogspot.com/ set up.

Metals utilized are usually steel or aluminum, although copper and zinc are likewise utilized. These roofing systems are practically upkeep totally free, and really resilient. They are not suitable for Do It Yourself setup, however. Standing-seam metal roofing systems have a life expectancy of 30 to 50 years, however as a reasonably brand-new item, info is still being gathered.

To take full advantage of life expectancy, regularly check them to make certain that fasteners and sealants have not stopped working, and check for distressed, bent, or slipped panels. Expenses for standing-seam metal roofings average about $10 per square foot for steel or aluminum, $13 per square foot for zinc, and $18 per square foot for copper.

If a metal roofing system is changed only when, expenses in today's dollars are For a house owner who lives in a house for 30 to 40 years prior to selling, a single $22,000 re-roofing expense might be the only one ever incurred if using metal roofing. And if you are purchasing a new house, buying one with a metal roof may mean you'll never face a re-roofing task at all.

ottoblotto/ Getty Images Clay tile roofs are extremely popular in the Southwest, however they can be found throughout the country, thanks to their extraordinary strength and durability. Conventional tiles are made from terracotta clay, but there are also ceramic tiles roofing systems (made of fired clay), as well as concrete tile roofings.

The Pros & Cons Of Different Roofing Materials

https://www.youtube.com/embed/zbmWX4DvFfY

They require a strong roofing framing adequate to hold the weight and needs to be installed by competent specialists. This may well be the only roofing system your house ever requires. Clay tile roofs regularly last 100 years or more when effectively kept. Tile roofing's Achilles heel is not decay, similar to wood shake or shingles, nor the sluggish sloughing off of mineral grains, just like composite shingles.